Evaluation/Analysis technology

Through the active utilization of CAE analysis, we facilitate the drastic reduction of numbers of testing or prototyping processes as well as reduction of development lead time at lower cost with high performance of the products which meet the various requirements of the customers.

✽CAE analysis means the abbreviation of “Computer Aided Engineering” which supports the development process of product with computer.

[ Analytical case 1 ] Analysis with two-dimensional profile

By using our unique in-house analytical system, we conduct the simulation of behavior of the sealing when the door is closed; then, we complete the optimum profile designing to support the door closing effort and sealing requirement at the same time.

|

Roof section This shows the representative case study of the analysis on how the profile and stress of the sealing change while the door is being closed. |

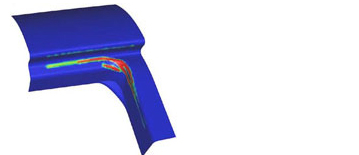

[ Analytical case 2 ] Analysis with three- dimensional profile

Door corner section requires advanced sealing design capability, and we conduct such simulation of rather complicated behavior of the section through three-dimensional CAE analysis.

| Door corner section(forming section of the weatherstrip mold) | ||

|

||

[ Analytical case 3 ] Corner adaptability analysis

When the part is mounted to vehicles, the shape of the part will change to the great extent at the corner section, in some case the sealing property deteriorates. We conduct the Corner bending capability analysis and design the profile, which is resistible to deformation, for securing the high sealing performance.

| Corner section beneath the hinge(assemble to the door panel) | ||

|

The figure on the left shows the stress distribution under the assembled condition with color difference. Those areas or points, upon which, the stress concentrate are identified and made use of designing work. | |

- Introduction to Nishikawa Technology TOP

- Design engineering

- ・Sealing design

- ・Mold design

- ・Device design

- Material engineering

- ・Rubber

- ・Thermo Plastic Elastmer

- ・Coating

- ・New material

- Method of process and engineering

- ・Multi-layered co-extrusion technique

- ・Production line

- Evaluation/Analysis technology

- ・CAE analysis

- ・Acoustic analysis

- ・ Performance evaluation

- NPS