Design engineering

We are engaged in the design of automotive door sealing systems responding to business inquiries from all of the OEMs in Japan. We also undertake specialized design engineering of seals for challenging requirements from overseas customers. We create “BEST-IN-CLASS” sealing designs that are applied to each category of sedan, coupe, SUV and other types of vehicles.

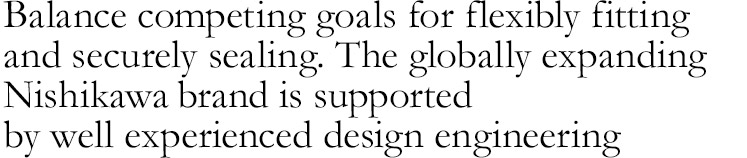

Weatherstrip for convertible type vehicle

It is no doubt that Nishikawa’s sealing is crystal perfect. The sealing design for convertible vehicles distinguishes Nishikawa from other competitors. The sealing design for the convertible vehicles requires complex sealing system. Nishikawa leads in this field with high technical proposal based on accumulated experiences and know-how as well as innovative idea.

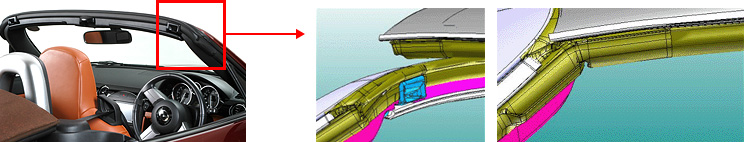

Weatherstrip for doors with wide opening

It is essential to hold advanced sealing design and development capability for weatherstrip to make passengers feel a freedom around the door or to make passengers get in or out from a car easily. Under the trend for multi-functional products, through the collaboration with OEMs, we propose flexible ideas to a new concept car. Many automakers give Nishikawa their patronage.

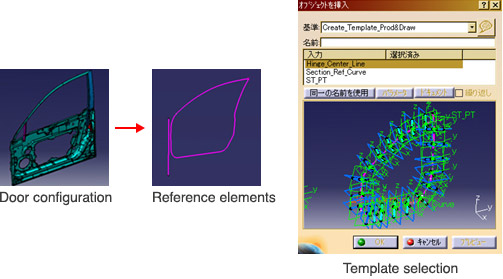

Template designing (Semi-automatic designing)

In creating the design and developing the concept, we make full use of 3-D CAD systems, and for supporting such activities, we have developed the “Template” as an in-house basic tool for design engineering. In this Template, we develop the seal structure to meet the specific vehicle design according to individual requirements. In the process of this development, we apply this Template-supported automatic design capability to the development of basic cross-sections, tooling and through to drawings, achieving stable product quality and reducing designing lead time.

Technology

- Introduction to Nishikawa Technology TOP

- Design engineering

- ・Sealing design

- ・Mold design

- ・Device design

- Material engineering

- ・Rubber

- ・Thermo Plastic Elastmer

- ・Coating

- ・New material

- Method of process and engineering

- ・Multi-layered co-extrusion technique

- ・Production line

- Evaluation/Analysis technology

- ・CAE analysis

- ・Acoustic analysis

- ・ Performance evaluation

- NPS